Custom 6-lobe socket head cap screws manufactured domestically in 18-8 stainless steel material at approximately 8,000 pcs. Our customer wanted us to provide these custom screws in black oxide finish after running them through ASTM A967 passivation. Partial unthreaded shoulder was incorporated and the thread was rolled instead of the cut alternative. Lead time for similar projects is currently running at 8-12 weeks from order confirmation.

Search Our Custom Fasteners

Friday, September 21, 2018

Custom 6-Lobe Socket Head Cap Screws - 6-32 X 1-1/4 In 18-8 Stainless Steel Material

Location:

Los Angeles, CA, USA

Monday, September 17, 2018

Custom Double End Studs In 18-8 Stainless Steel Material - with AA1096 microspheres thread locking patch

These are custom double end studs made using 303 stainless steel (18-8 stainless steel) for our electronics manufacturing customer. Domestically made at approximately 4,000 pcs these parts were made to the drawing shown below with AA1096 microspheres thread locking feature one the shorter threaded end. 1/4-20 thread was incorporated on the long threaded portion, while 10-24 was used for the shorter end with the thread lock patch. A #2 square drive was broached on the 1/4-20 side as well.

Location:

Los Angeles, CA, USA

Friday, September 14, 2018

Custom Deep Recess Phillips Drive Screws - #8 X 2" Phillips Pan Type A Sheet Metal Screws

At first glance these custom deep recess phillips drive screws seem like ordinary sheet metal screws. For the most part that is true - the Type A thread and head dimensions are essentially per IFI specs without any modifications. A closer look however will reveal a significantly deeper recess in the phillips drive. Standard #8 phillips drive for a pan head reaches a depth of .108" while this custom part has a recess depth of .120" to .122" - a significant difference when it comes to improved engagement and faster/easier use on the production floor. This improvement in speed and engagement was the main driver behind our customer's request for this modified sheet metal screw, particularly important when some of the depth is used for paint when the screw heads are painted a variety of different colors.

Labels:

custom deep recess screws,

custom sheet metal screws,

custom stainless screws,

custom stainless steel sheet metal screws

Location:

Santa Ana, CA, USA

Tuesday, September 11, 2018

Custom Metric 316L Set Screws - M5-0.8 X 6MM Short Dog Point Socket Set Screws

We ran an order of these custom metric 316L set screws with a short dog point at just 66 pieces using domestic production. Lead time was relatively short at just 2-3 weeks from confirmed purchase order receipt. A short .059 dog point was incorporated and a 2.5MM hex socket drive was broached for speed and cost efficiency. Overall length was set at 2.36 inches and the tolerance on all dimensions was set at +/- .005 inches. Great detail can be seen in the print included here as a reference.

Labels:

316L screws,

316L set screws,

custom 316 set screws,

custom 316L screws,

custom dog point screws

Location:

Philadelphia Metropolitan Area, USA

Monday, September 10, 2018

Orange Painted Sheet Metal Screws - #8 X 3/4" in 18-8 Stainless Steel

These orange painted sheet metal screws are one of the brighter and more colorful painted screws we supply our customer base. Most of the painted screws are in more subdued varieties of white, grey, and brown to match a variety of paneling used by our customers in their respective assembly lines. The base screw itself is a standard off the shelf 18-8 stainless steel #8 X 3/4" type A sheet metal screw. Lead time for this color is similar to the others at 2-3 weeks from order confirmation but an expedited processing option is typically available upon request.

Labels:

custom painted bolts,

custom painted screws,

matching painted screws,

painted sheet metal screws

Location:

Santa Ana, CA, USA

Friday, September 7, 2018

Custom A286 MS24693 Screws - Phil Flat 4-40 X 1/4"

These custom A286 MS24693 screws can look deceivingly simple at first glance. The A286 material was a large deviation from the typical MS24693 specifications and the parts had to be heat treated to 140 KSI. To finish off the production process the parts went through a NADCAP certified sand blast and descale & passivation process per AMS2700 Type 2 Class 1. The production consisted of approximately 50,000 pcs and was completed domestically. NACAP cert for the passivation was provided together with material cert and certificate of conformance.

Location:

Los Angeles, CA, USA

Wednesday, September 5, 2018

Chrome Plated Phil Pan Hi-Lo Screws - 316 Stainless Steel Material With RoHS Compliant Tin Cobalt Finish, #10-16 X 3/4"

Another part to add to our growing list of custom tin cobalt and standard chrome plated fasteners. These chrome plated phil pan hi-lo screws were manufactured overseas at approximately 50,000 pcs and supplied to our customer on a revolving blanket purchase order basis. They measure #10-16 X 3/4" and are identical outside of the length to the #10-16 X 1/2 version we have supplied for a number of years already. 316 stainless steel material is used for optimal corrosion resistance, which is further enhanced with the chrome plating for use in highly corrosive environments.

Labels:

chrome plated bolts,

chrome plated hilo screws,

custom 316 stainless hardware,

custom 316 stainless screws,

custom hilo screws

Location:

Los Angeles, CA, USA

Tuesday, September 4, 2018

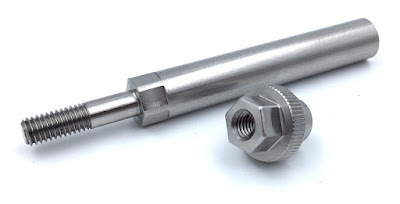

Custom 316L Machined Hardware - 6MM X 1.0M Thread & Straight Nurl Application On The Nut

We had 100 pcs of this mating custom 316L machined hardware produced domestically with a lead time of approximately 4 weeks. These 100 pcs were to be used in testing prior to larger volume production. The rod pieces measures 90MM in overall length and the knurled nut measures 17MM in overall height. Getting the nut fully tapped turned out to be the trickier part of the process - the taps kept breaking before the full depth was reached. After a few adjustments and a change-up on the thread tap style used that last issue was finally resolved. Material certs were provided with the parts per customer's original request.

Labels:

316L nuts,

316L screws,

custom 316L hardware,

custom 316L nuts,

custom 316L parts,

custom 316L screws

Location:

Los Angeles, CA, USA

Subscribe to:

Posts (Atom)